eKETL: affordable wind tunnel for zero-emission propulsion testing Stess analysis: case study |

The e-KETL project, funded by the NATEP programme, has developed a novel suction wind tunnel concept based on the ejector principle at S&C Thermofluids' existing Kemble Engine Test Laboratory (KETL) to allow configurable e-propulsor dynamic and cross-wind testing. The project is led by Greenjets UK Ltd and more information on the concept can be found here.

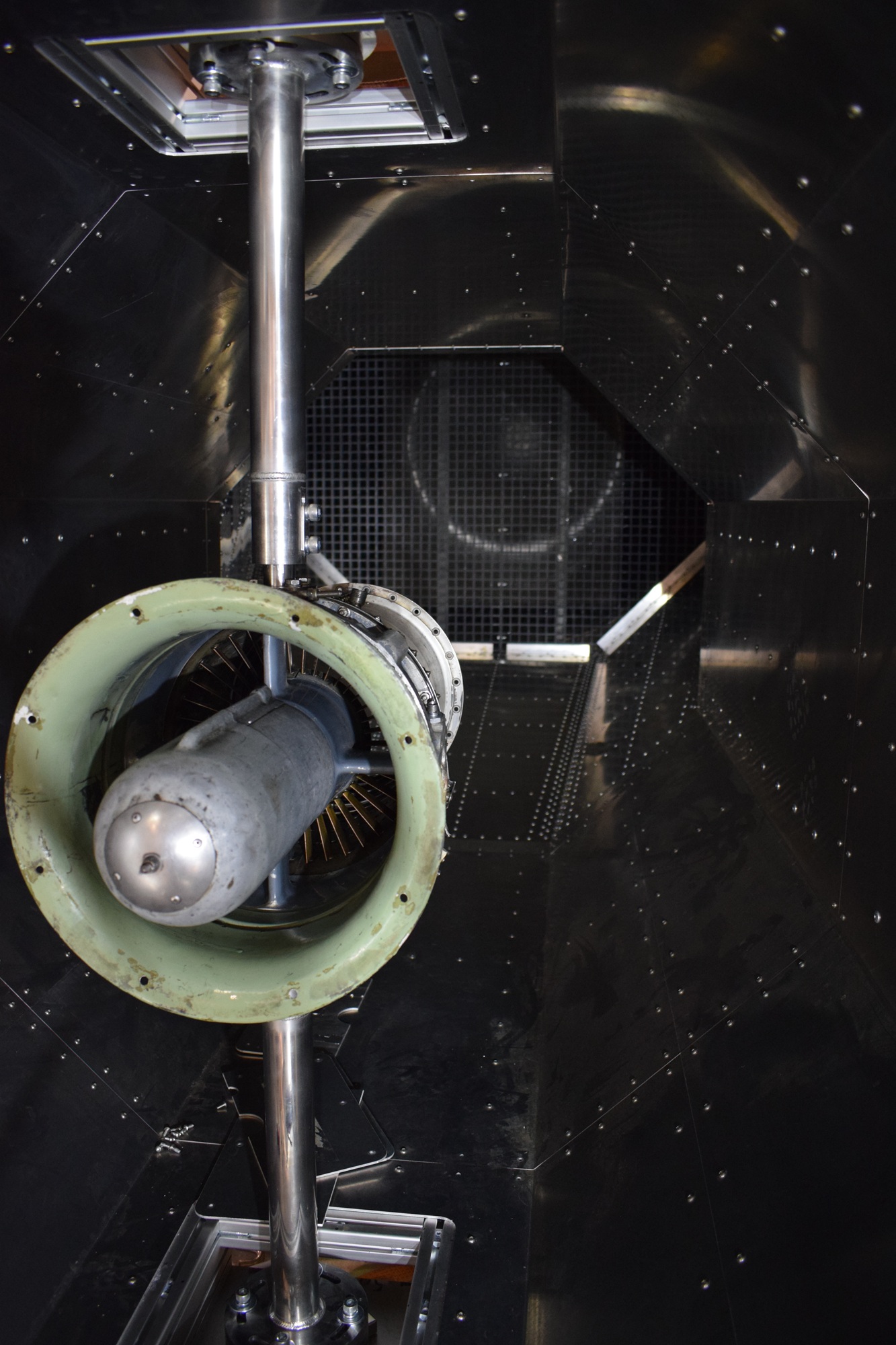

| The work involved mounting an existing engine owned by S&C Thermofluids, the ALF502, into the detuner infrastructure at the KETL. The exhaust from the ALF502 entrains a significant amount of free air within the detuner by the ejector principle, and hence upstream of the detuner a working section was designed to create a simulated wind tunnel. The combined mass flow of the ALF502 intake and the entrained air results in flight speeds of up to 150m/s in the working section. Electric propulsors and other novel flight hardware can therefore be tested at flight velocity - and the use of a floating sting arrangement on a 6-axis load cell allows thrust measurement in cross-wind configurations. The ALF502 had not previously been operated by S&C Thermofluids so a package of work was undertaken to understand the mounting requirements. A stress analysis study was contracted to Technia UK to assess the structural integrity of the design whilst under the full load of the engine in operation. Technia UK has written a case study on the work which is available here. The commissioning activity was completed in March 2025 and we would be more than happy to discuss tailoring the capability to your future testing requirements. Get in touch to check our rates and availability. |

|

© S & C Thermofluids Ltd 2024 |

S & C Thermofluids Ltd The Old Tannery, Kelston, Bath, BA1 9AN |

|